Some Development Images

Built for my primary school aged sons the “Buggy” is a two-boy/girl battery powered 4WD tandem off-roader.

Rather unusual in appearance the design has features required for effective off-road use. The design is also strongly influenced by cost and manufacturability constraints. (It's as cheap as I could make it with basic metal working tools.)

As an electric vehicle it’s quiet and clean in operation and easy to keep (no IC engine to maintain). The articulated two-frame arrangement allows steering without the need for complex steering components and continuous 4 wheel ground contact without complex suspension components. This makes it easier to make and limits cost. It does have disadvantages for stability on cornering but these are overcome by mechanically limiting the articulation angles (steering and twist).

24” mountain bike wheels provide good grip, capability for climbing kerb-sized steps and generous ground clearance. They are lightweight and are easy to source.

Each wheel is driven independently by a DC PM motor; a 4WD arrangement

that, combined with the articulating frame to keep the wheels on the

ground, best converts the available vehicle weight into useful tractive

effort.  The

motors are connected in parallel but still allow effective differential

action when turning; the arrangement does not need the expense of

differential gearboxes. Again reducing cost and complexity. They also

ensure continuous drive to the remaining wheels should one or more

wheel slip. The principal disadvantage of the arrangement is the cost

of 4 motors; ISKRA units were the least expensive I could find.

The

motors are connected in parallel but still allow effective differential

action when turning; the arrangement does not need the expense of

differential gearboxes. Again reducing cost and complexity. They also

ensure continuous drive to the remaining wheels should one or more

wheel slip. The principal disadvantage of the arrangement is the cost

of 4 motors; ISKRA units were the least expensive I could find.

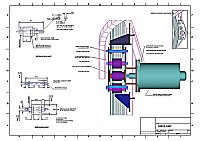

The mechanical transmission is in the form of belt friction drives to the tyres. These drives are compact, easily fitted and removed and simpler and cheaper to manufacture than other possible drive arrangements. Requirements for the alignment and positional control of “hard points” on the structure are minimised also and wheel removal and replacement is made straightforward. The drives are relatively insensitive to minor wheel damage and can be adjusted to vary slip load, a feature which can protect the motors from overload and potential stall conditions.

Notwithstanding their advantages the belt friction drives are a weaker area of the design and are less durable (belt life) and less efficient than would be ideal. These issues could be addressed with further engineering development but an alternative, though similar, low cost drive is being considered which has all of their good features and less of the bad.

Bringing the vehicle

to life...the controller. Initially a 4QD

Pro 120 24V

controller (shown during assembly) drawing power from two 12V 40Ah

Global/Yuasa batteries completed the drive system. However the current

draw from the 4 motors under unusual overload conditions proved a

little too much for the Pro 120 and an upgrade to the 4QD Series was

made. The controller provides forward and reverse motion with smooth

and sensitive speed control which can be tuned to suit the vehicle and

driver. It also has several valuable self-protection features, for

example it can handle the vehicle being thown into reverse when going

flat-out forwards (something the kids do from time to time). The kids

have picked up how to operate the vehicle using the speed control lever

and reversing switch without much difficulty (this includes learning

some pretty impressive reversing manoeuvres).

Bringing the vehicle

to life...the controller. Initially a 4QD

Pro 120 24V

controller (shown during assembly) drawing power from two 12V 40Ah

Global/Yuasa batteries completed the drive system. However the current

draw from the 4 motors under unusual overload conditions proved a

little too much for the Pro 120 and an upgrade to the 4QD Series was

made. The controller provides forward and reverse motion with smooth

and sensitive speed control which can be tuned to suit the vehicle and

driver. It also has several valuable self-protection features, for

example it can handle the vehicle being thown into reverse when going

flat-out forwards (something the kids do from time to time). The kids

have picked up how to operate the vehicle using the speed control lever

and reversing switch without much difficulty (this includes learning

some pretty impressive reversing manoeuvres).

In addition to driving the vehicle the motors and control system

provide braking which is effective in stopping vehicle quickly and is

regenerative. Here the inefficiencies in the drives actually assist

slowing (although they don’t help the useful recovery of

energy through

the controller). Given the 4WD design and the restricted and controlled

use of the vehicle, mechanical brakes have not yet proven necessary,

however foot or hand operated bike calliper brakes could be fitted

easily.

The vehicle design works well. The 4WD is effective in propelling the vehicle on grass, gravel, soil etc and on gradients. Steering is effective and frame articulation is effective in maintaining wheel/ground contact on uneven surfaces. Top speed and acceleration are impressive for a childrens' buggy.

The principal weakness of the design is the limited battery life. The batteries are discharged after about 1 hr 15 min continuous operation although this may take several hours to achieve given the stop-start way in which the Buggy is used. Whereas doubling the battery capacity is a practical solution the better design response is to address the underlying causes, which are vehicle weight and drive inefficiencies. Version two of the buggy is under development and incorporates significant improvements in these areas and others.

© This site is copyrighted. If you'd like more information or have any comments please feel free to contact me at