Electrical and Control System Details

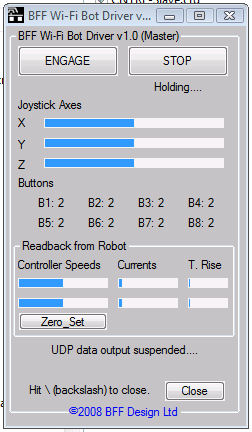

I've

written the Wi-Fi Bot Driver software application which handles the comms

over the wireless network. This allows the joystick control signals to be communicated

from the fixed PC to the mobile robot and also allows a live

read-back of the condition of the motor speed

controllers on the bot. This is a key part of the control system. It is made up of two programs - Sender and Receiver,

which run on the fixed and mobile PC's respectively. The Sender program

reads the state of the joystick on the fixed PC and transmits this using

UDP protocols to the receiving PC. If required the Sending program can

instead output the control signals directly to a serial port on the fixed PC.

This is useful for wired debugging of the bot or for onward transmission

by

wireless telemetry links.

I've

written the Wi-Fi Bot Driver software application which handles the comms

over the wireless network. This allows the joystick control signals to be communicated

from the fixed PC to the mobile robot and also allows a live

read-back of the condition of the motor speed

controllers on the bot. This is a key part of the control system. It is made up of two programs - Sender and Receiver,

which run on the fixed and mobile PC's respectively. The Sender program

reads the state of the joystick on the fixed PC and transmits this using

UDP protocols to the receiving PC. If required the Sending program can

instead output the control signals directly to a serial port on the fixed PC.

This is useful for wired debugging of the bot or for onward transmission

by

wireless telemetry links.

The Receiver program running on the board notebook/laptop converts

commands received over the network into a local serial output which is

read by a PICAXE micro controller based processor unit (SPU) to provide

the local control over the machine. The Receiver program exports the

state of three axes and 8 button buttons on the sending joystick and

could be used to provide a serial feed to any microcontroller based

applications that can read serial data.

The bot driver software uses standard network IP addresses and port

numbers to identify the participating PC's. The data flow can be

interrupted at either PC to disable the robot.

The bot Signal Processor Unit reads the serial data from the notebook PC

(or direct from the fixed PC) and mixes the joystick forward/reverse and left/right axis data to

determine speed and direction required of each drive motor, it then

sends the speed and direction instructions to the motor speed

controllers on the robot. It also instructs RC style servos which

provide pan and tilt for the onboard webcam  (so you can see where you

are going if the robot is in a different room or off exploring in the

back garden).

(so you can see where you

are going if the robot is in a different room or off exploring in the

back garden).

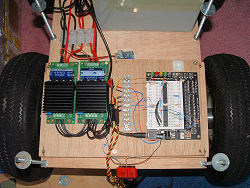

The

overall system wiring for the robot is shown above. The SPU is built on

the picaxe experimenter board and uses two 28X1 picaxe chips. The master

chip handles the serial comms with the laptop and drives two Devantech

MD03

motor controllers on an I2C bus. It also passes the state of the

designated pan and tilt joystick buttons on the the 2nd or slave 28X1

chip which issues servo pulse commands to drive two camera position

servos.

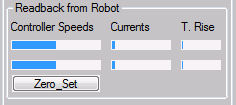

Monitoring the Robot's Condition

The communications provided by the robot driver

software is two-way. The on-board SPU reports the motor speed controller

speed settings, current flow and temperature back to either the Notebook

PC carried on the bot (for onward transmission to the master PC) or

directly to the master PC. This feedback data is displayed live on the

sender program window. This gives the driver live feedback of the

current draw and temperatures of the speed controllers - it makes for

interesting watching.

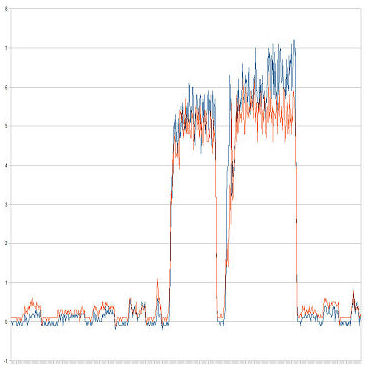

The

Bot Driver Software is also able to dump this feedback data to a text

file where the data can be inspected more closely. For example the trace

below shows the current flow in the MD03 speed controllers during simple

straight line travel and then during full on-the-spot skid-steer

rotations. It is generally known that skid steering consumes much more

power than more conventional steering approaches but it's interesting to

see the effect directly.

The

Bot Driver Software is also able to dump this feedback data to a text

file where the data can be inspected more closely. For example the trace

below shows the current flow in the MD03 speed controllers during simple

straight line travel and then during full on-the-spot skid-steer

rotations. It is generally known that skid steering consumes much more

power than more conventional steering approaches but it's interesting to

see the effect directly.

|

Motor Controller Currents during

Skid-Steer Turns |

The trace is a bit noisy but small up/down steps can be

seen over the initial part of the trace matching the initial simple

forward and reverse straight line motion of the bot. The current draw in

each controller looks like it is approximately 0.3/0.4 Amps - ie it

requires little effort to travel on the flat in a straight line. However

the jump in the current draw during the skid-steer turns can be seen

clearly, The current draw rises to roughly 5 to 6 Amps with some

peaks higher as the speed of the turns gets faster. I haven't included a

temperature trace but it shows the controller temperatures climbing

during the period of higher current draw. The MD03's are rated for 20

Amps and the 250W motors for 14 Amps so the currents are still well

within capacity but it is still interesting to see the scale of the

higher power demand as the wheels are dragged and spun during the turns.

Back to Page 1......

On to Page 3 for Machine Vision