The

motor speed controller is a key element in the

electrical drive system of an electric vehicle. What does it do? The DC motor

speed controller takes the nominally fixed voltage from the

power source, usually your battery pack, and outputs a

variable voltage supply needed to control the motor

speed. Its voltage output to the drive motors changes in

response to control signals supplied by the user – from

a foot or thumb accelerator or a joystick control say.

In modern controllers the main voltage

conversion is done very efficiently using PWM techniques, with much much less

wasted energy than a variable resistor arrangement and,

given a good quality controller, with very smooth speed

control results.

The

motor speed controller is a key element in the

electrical drive system of an electric vehicle. What does it do? The DC motor

speed controller takes the nominally fixed voltage from the

power source, usually your battery pack, and outputs a

variable voltage supply needed to control the motor

speed. Its voltage output to the drive motors changes in

response to control signals supplied by the user – from

a foot or thumb accelerator or a joystick control say.

In modern controllers the main voltage

conversion is done very efficiently using PWM techniques, with much much less

wasted energy than a variable resistor arrangement and,

given a good quality controller, with very smooth speed

control results.

Motor controllers for battery electric

vehicles also bring other valuable control functions –

easily reversed drive, top speed limiting, control over

acceleration and deceleration ramps, over-discharge

protection for the batteries and in “4 quadrant” units

dynamic regenerative braking capabilities in which the power

generated by the motors as they slow a vehicle is fed back

into the battery pack.

It is possible to make an electric vehicle work without a

modern controller but using one provides many advantages

in terms of performance, controllability and efficiency.

The latter issue is important because the Achilles Heel

of most EV's is the amount of energy that can be stored

in a reasonably sized battery pack – loosing a

significant proportion of this through inefficient speed

control circuitry is just plain daft.

DC battery motor controllers are

rated by voltage and current. If you think back to your

high school physics you might remember that electrical

power (in watts) in a DC circuit can be calculated from

P= I x V where I is current in Amps and V is voltage. A

typical smallish 24V 75 Amp controller therefore has an

electrical power output capacity of 24 x 75 = 1800 W or

1.8 kW, about 2.5 Hp. Similar  controllers

are available right up to 48V x 300 Amp units with

nominal power outputs of 48 x 300 = 14400 Watts, about

20 Hp. Note that these electrical powers are not what's

finally available as mechanical work output at the drive

wheels. Inexpensive DC motors may have efficiencies

around the 75% to 85% mark and some energy will be lost

in the mechanical transmission also. Perhaps our 2.5 Hp

electrical output will end up as about 1.75 Hp at the

drive wheels.

controllers

are available right up to 48V x 300 Amp units with

nominal power outputs of 48 x 300 = 14400 Watts, about

20 Hp. Note that these electrical powers are not what's

finally available as mechanical work output at the drive

wheels. Inexpensive DC motors may have efficiencies

around the 75% to 85% mark and some energy will be lost

in the mechanical transmission also. Perhaps our 2.5 Hp

electrical output will end up as about 1.75 Hp at the

drive wheels.

When selecting a controller try to

download the full spec sheet or manual from the

manufacturer and read the conditions that apply to the

current ratings – they are usually time limited and,

because in the end it's controller heating that's

usually the concern, effective heat sinking can make

quite a difference. In my experience however it's much

easier to keep a properly rated controller cool than the

motors it supplies!

Manufacturers' usually also provide

clear instructions on wiring and circuit diagrams -

check their web sites.

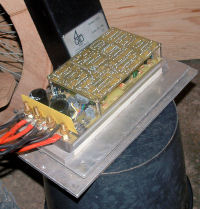

I use mainly UK built controllers from 4QD

and have generally had very good service from them. For the

lower power vehicles their low cost Vortex units have worked

well - two basic versions are available with 40 & 75 Amp

ratings well suited to the 250W and 500W vehicles. For

heavier duty we use the 150Amp 4qd series controller shown

above with the cover removed. There are several other good manufacturers of similarly

rated units - follow the supplier links and have a look

around for yourself.

A lower cost alternative can be to use

electric scooter controllers. These tend to be made in the

far east and can be a lot less expensive although perhaps

with fewer features and lower quality. If you go this route

check the number of "quadrants" of the design - many scooter

controllers do not run in reverse. Check also the

requirements for speed control input - they often require a

hall effect speed input "pot". Check

PartsForScooters

for some examples of scooter controllers.

A

newer experience for me is using smaller H-Bridge type speed

controllers on the DIY Motion Cockpit. These don't have many

of the EV related features that the 4QD controllers have and

are better in rapid or frequent reversing applications.

Devantech are one supplier and I've used their 20 Amp MD03

units. These are of lower current capacity than most EV

related controllers but are also quite a bit cheaper. As

with other types they can be controlled from programmable

microcontrollers and are often used for robot applications.

Many offer a number of different ways of supplying the speed

and direction demands including straight analogue voltage

inputs, PWM voltage inputs and other more sophisticated

methods such as Serial communications and Philips I2C bus

communications - read up on the technical data to see what's

what.

A

newer experience for me is using smaller H-Bridge type speed

controllers on the DIY Motion Cockpit. These don't have many

of the EV related features that the 4QD controllers have and

are better in rapid or frequent reversing applications.

Devantech are one supplier and I've used their 20 Amp MD03

units. These are of lower current capacity than most EV

related controllers but are also quite a bit cheaper. As

with other types they can be controlled from programmable

microcontrollers and are often used for robot applications.

Many offer a number of different ways of supplying the speed

and direction demands including straight analogue voltage

inputs, PWM voltage inputs and other more sophisticated

methods such as Serial communications and Philips I2C bus

communications - read up on the technical data to see what's

what.

Interestingly it is not uncommon for robot builders to make

their own controllers, and if you are interested in more

detail there are some good sites which can help give insight into

how they work and how they can be put together - here's just

a few:

http://homepages.which.net/~paul.hills/SpeedControl/SpeedControllersBody.html

http://www.hassockshog.co.uk/motor_controller_description.htm

And the Open Source Motor Controller Project here

http://tech.groups.yahoo.com/group/osmc/