In my experience one of the hardest things to get right when building

an electric (or other) buggy is getting the mechanical drive from the

motors to the drive wheels right. Over the years I've tried all sorts of novel mechanical power transmission methods from friction drives (Tandem Buggy) and inverted toothed belt drives (Sporty) to sprocket on chain-rim drives (Mini Tractor). Some of these work better than others, some are more reliable than

others. Perhaps not surprisingly however, if you can make them,

the drives that work best are those most commonly used in the

engineering industries - involute gear, chain & sprocket or belt & pulley

drives.

For the DIY-er or home-builder there's a big

problem here however - usually gears or sprockets are keyed or splined

to shafts, shafts are stepped in diameter to fit into bearings, metal

bearing housings are bored-out to accept the bearings and the housings

are precision machined in the walls of steel or aluminium gearbox

casings. How do you do any of this if you

don't have access to the range of specialised metal cutting machine tools usually found in an engineering works?

The answer is to

avoid doing it - through some intelligent design of the gearbox. The

gearboxes we have developed for use in our most recent designs use

carefully selected combinations of common engineering components,

adhesive bonding methods and particular build constructions

and procedures that allow them to be built with much less

sophisticated tooling.

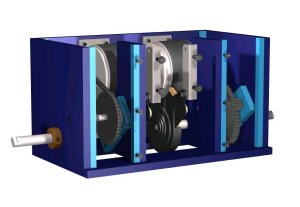

There are three

boxes shown on the site - one single motor unit and two double motor units, one of which

has built in band-brakes (as used in the Go Kart

). Some of their design features are:

- Self contained - multiple drive components don't

need to be separately attached to the buggy main frame or chassis.

Drive wheels are attached directly to the output shafts.

- Timber cases - easier to make and easy to secure to.

- A combination of roller chain and gear

stages to obtain overall speed reduction ratios from about 10:1 to 27:1

from the motor output shaft and wheel axle speeds. A range of different

final stage gears can be used at the build stage to set the reduction

ratio needed for a particular application.

- 1st stage (motor) chain drive which is more

forgiving of slight inaccuracies in the motor positioning than a geared

1st stage - this allows the motor fixing methods to be simple.

- Adhesive bonding of gears/sprockets to

shafts - no need for splines, keys or stepped shafts. The only

machining required is to drill-out gear/sprocket bores to match shaft

sizes, no stepping of shaft diameters.

- Inexpensive needle roller bearings on all shafts.

- Steel shafts for strength with bench ground end flats for torque attachments..

- Build procedures to allow accurate positioning

of bearing housings in the casing to set correct shaft centre distances

and alignments.

With the electric scooter motors we use in the gearboxes a range

of output shaft speeds are obtained between about 150 rpm and 370 rpm

depending on which 2nd stage gears are used. The motors have rated

power outputs of 250W giving a total of 500W output for the double

motor unit. The braked unit has built-in scooter band brakes which

brake directly the final axle - this provides mechanical braking

which is independent of the electrical drive. Note however that

band-brakes are more effective in one direction than the other so the

braked unit has particular "forward" and "reverse" directions.

With the electric scooter motors we use in the gearboxes a range

of output shaft speeds are obtained between about 150 rpm and 370 rpm

depending on which 2nd stage gears are used. The motors have rated

power outputs of 250W giving a total of 500W output for the double

motor unit. The braked unit has built-in scooter band brakes which

brake directly the final axle - this provides mechanical braking

which is independent of the electrical drive. Note however that

band-brakes are more effective in one direction than the other so the

braked unit has particular "forward" and "reverse" directions.

By using gear and

roller chain stages and roller bearings throughout, the boxes are

efficient and loose little drive energy in transmission.

Importantly for buggy use they are both reversible (can be driven in

reverse) and back-driveable (can be driven from the output shaft). This

later characteristic allows the use of "4 quadrant" motor

controllers to provide some dynamic, re-generative braking for the

application. Another practical application of this is to allow the

vehicle to be towed relatively easily when the drive motors are

isolated from their controller.

Follow the links below for .pdf files of the gearbox assemblies.

One

final note (and a wee admission of failure), try though we might I could not figure

out how to fix the final stage gear to a suitably sized final

drive shaft without drilling a hole in the gear bigger than most common

bench drills could handle. The final shaft is approx 16 mm in diameter

to give bending strength required to support the wheel loads. 16 mm in

steel is too big for a small bench drill. So this remains the one bit

most competent DIY-ers, who don't have or have access to a small lathe,

will find problems with. The solution is straightforward however - get

the gear manufacturer to do it for you - many will happily, for a small

additional charge, modify the bores on their gears to suit customers.

See the assembly sheets

here for the

gearbox with brakes!