My

experience of using RC (radio control) style Servos is

fairly limited and recently acquired, and I have to

admit to previously having some confusion in my mind

about these devices and their relationship with servo

motors and servo drives more generally.

My

experience of using RC (radio control) style Servos is

fairly limited and recently acquired, and I have to

admit to previously having some confusion in my mind

about these devices and their relationship with servo

motors and servo drives more generally.

Servo

motors are a type of electric motor designed to be used

as part of a larger servo control system, often using

closed loop control methods. These mainstream “servo”

systems are widely used in industry to drive loads of

various kinds and sizes with good control over the

driven motion – for example by effectively controlling

the position, speed or acceleration of the moving load.

The RC

style Servo is, however, not an electric motor, although

it does contain one – it is effectively an entire

position feedback closed loop control system packaged in

a compact casing. They contain the electric drive motor

(usually DC PM) with mechanical reduction gearing, position

feedback sensor and the closed loop control and motor

drive electronics. The drive output is usually via a

limited rotation shaft (to which various torque arms can

be fitted) and the input signal is a position demand

signal where the required position is encoded in a

series of length controlled low voltage pulses.

The range

of available RC servos is mind boggling, especially to a

beginner such as me. Physical size, output torque, speed

of movement, range of movement, position resolution,

backlash and build quality seem to be the main

parameters that differentiate the available choices. I

did find a fair amount of information on the web about

the use of RC servos in different applications and that

helped in making buying choices - do

your own search to

see.

Generally

they are not large devices, the above image shows a

Hitec HS-815BB “Mega Sail Servo” which, with an output

torque of about 25 kg.cm (~2.5 Nm). This is pretty much

at the top of the available torque output range. There

are a few industrial sized servos around but these are

much more expensive. The torque arm on the Hitec has a

limited working travel of about +/- 90°

(mechanical travel is larger) and has a no-load speed of

about 0.14 sec/60° when working at 6V.

Generally

they are not large devices, the above image shows a

Hitec HS-815BB “Mega Sail Servo” which, with an output

torque of about 25 kg.cm (~2.5 Nm). This is pretty much

at the top of the available torque output range. There

are a few industrial sized servos around but these are

much more expensive. The torque arm on the Hitec has a

limited working travel of about +/- 90°

(mechanical travel is larger) and has a no-load speed of

about 0.14 sec/60° when working at 6V.

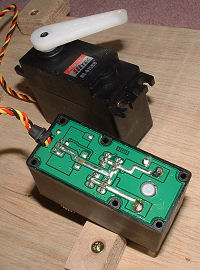

The image right

shows the servo with the top cover removed. You can see

the built in geared transmission – in this case a

5-stage reduction using plastic straight spur gears to

reduce the high motor shaft speed to the approx 1 rev/s

needed at the output shaft. This servo also has a ball

bearing mounted final drive shaft although less

expensive units may use plain bearings. The second image

below shows the base of the servo removed where the PCB

of the drive electronics can be seen. The drive motor

and position feedback potentiometer lie within the

casing. The gear train is of good quality and there is

very little backlash noticeable at the torque arm even

with the relatively large number of reduction stages.

So

they are capable of fairly high speed motion over a

limited range of travel. The speed of motion will slow

at higher loads and when the applied load is too high

the drive motor will stall. My interest in using this

servo was for a joystick force feedback project and for

this type of work where a smooth, vibration-free

movement under load is required the servo is not an

ideal solution. Under load the arm vibrates very

slightly at the refresh frequency of the internal

position control loop and this can be felt. For many

less sensitive positioning applications the device would

perform satisfactorily. This particular RC servo can be

driven fairly easily from the torque arm when it is not

powered, this is probably down to the straight spur gear

transmission - other servos with other types of geared

transmissions may not be so easily back-driven.

So

they are capable of fairly high speed motion over a

limited range of travel. The speed of motion will slow

at higher loads and when the applied load is too high

the drive motor will stall. My interest in using this

servo was for a joystick force feedback project and for

this type of work where a smooth, vibration-free

movement under load is required the servo is not an

ideal solution. Under load the arm vibrates very

slightly at the refresh frequency of the internal

position control loop and this can be felt. For many

less sensitive positioning applications the device would

perform satisfactorily. This particular RC servo can be

driven fairly easily from the torque arm when it is not

powered, this is probably down to the straight spur gear

transmission - other servos with other types of geared

transmissions may not be so easily back-driven.

There are

many proprietary RC servo controllers available to drive

RC servos. Depending on type these can be interfaced

with standard radio control receivers, several types of

micro controller or to USB or serial ports on a PC, so

the range of control options is fairly large. The image

below shows a Pololu 16 Servo Serial controller which I

used to drive the servos from a PC.