|

Because

of its tilting action this 3-wheeler Scooter design is structurally a

bit more complicated than the Trike

on the site. It's a more interesting ride though as it has to

be balanced much in the same way as a bike. It's still

“buildable” by competent DIY ers and home-builders

using

non-specialised tools and materials. Other than the tilting structure

it uses the same drive and steering elements as the Trike so

much of

the description given below is the same.

Quick movie clip of the scooter in action (1.5 Mb)

The scooter

has a mainly timber “glued and

screwed”

construction, a rear double

reduction drive gearbox, 10” pneumatic wheels and a front

disc brake. Several important strength

components are made of

steel and throughout use is made of standard

stock engineering components such as

bearings, bright steel bar,

gears,

sprockets etc.

It's

laden center of gravity is a bit forward of the rear wheels which gives a

balance between weight over the rear wheels for traction and download at

the front for steering and braking.

The scooter is driven by either a single or

double motor gear box -

both of which use 250W electric scooter

motors which are commonly

available in both here in the UK and in

the

US.

The single motor scooter is the

simpler of the two and has fewer parts but the simplicity and lower

cost has the obvious consequence of lower power output (250W). There is

also a traction related drawback - to keep the high levels of

manoeuvrability offered by the single front steering wheel I found it

was best with the single motor drive to drive only one of the rear

wheels and leave

the other free-wheeling; the alternative was to drive both rear wheels

through a fixed rear axle – an arrangement I experimented

with but found, because there is no differential action, that the

steering effectiveness was badly compromised. I found that the

traction from one driven wheel is easily sufficient to drive the

scooter on reasonably good drives surfaces – see the movie

clips below.

The

turning

problems are resolved with the double motor driven option - each

of the rear wheels is driven by its own motor, each develops traction

and the speed/torque characteristics of the

motors ensures effective

differential action when they are wired in parallel to the same controller. A further key advantage

of the double motor drive is the higher power output (500W). In some

vehicles this could be exploited though a higher speed transmission to

the wheels but with this vehicle it's probably better to use the power

to increase the available wheel drive torque and allow the Scooter to

be used on poorer surfaces found in many gardens – hard

gravel paths, mown grass lawns etc. The

turning

problems are resolved with the double motor driven option - each

of the rear wheels is driven by its own motor, each develops traction

and the speed/torque characteristics of the

motors ensures effective

differential action when they are wired in parallel to the same controller. A further key advantage

of the double motor drive is the higher power output (500W). In some

vehicles this could be exploited though a higher speed transmission to

the wheels but with this vehicle it's probably better to use the power

to increase the available wheel drive torque and allow the Scooter to

be used on poorer surfaces found in many gardens – hard

gravel paths, mown grass lawns etc.

These characteristics and the

10” wheels

and relatively low ground clearance (about 3.5”) mean the

Scooter isn't really an off-roader and is best suited for good (hard

and flat) drive surfaces. The double motor drive though extends the

capability to hard gravel and cut grass lawns and modest hill climbing.

The gearbox is a

key part of the design and is described in more detail here. The boxes are

home-built too and are efficient, reversible, back-driveable and allow

choice in the overall reduction ratio and hence output

speed – watch this though, using too high an output speed

simply results in over torqued, over heated motors which won't last. We

have found that gearing to produce a top speed of about 7 to 8 mph is

probably the maximum for use on good drive surfaces and less than this

for poorer higher drag surfaces. Clearly the higher power version does

better with the heavier riders and poorer surfaces. An interesting

exercise is to check the specs for 250W and 500W electric scooters you

can buy – see how they compare. The gearbox is a

key part of the design and is described in more detail here. The boxes are

home-built too and are efficient, reversible, back-driveable and allow

choice in the overall reduction ratio and hence output

speed – watch this though, using too high an output speed

simply results in over torqued, over heated motors which won't last. We

have found that gearing to produce a top speed of about 7 to 8 mph is

probably the maximum for use on good drive surfaces and less than this

for poorer higher drag surfaces. Clearly the higher power version does

better with the heavier riders and poorer surfaces. An interesting

exercise is to check the specs for 250W and 500W electric scooters you

can buy – see how they compare.

The electrical system is standard for

small electric vehicles ie motor(s), motor controller,

batteries and

speed/reverse/ignition controls. The controller used on this single

motor scooter is the 24V 40 Amp Vortex

controller from 4QD which has worked well – the 75Amp version

is probably needed for the double motor drive. Room for two 12 V 38AmpH deep

cycle batteries wired in series is built-in to the structure and these give

a continuous

running time between charges of about 2 hours for the single motor

drive which isn't bad. For the same driving conditions the range for

the double motor version will be a bit less – though not

half, the power consumed depends mainly on vehicle duty and weight not

number of motors. Running time reduces with use on harder

driving surfaces. The electrical system is standard for

small electric vehicles ie motor(s), motor controller,

batteries and

speed/reverse/ignition controls. The controller used on this single

motor scooter is the 24V 40 Amp Vortex

controller from 4QD which has worked well – the 75Amp version

is probably needed for the double motor drive. Room for two 12 V 38AmpH deep

cycle batteries wired in series is built-in to the structure and these give

a continuous

running time between charges of about 2 hours for the single motor

drive which isn't bad. For the same driving conditions the range for

the double motor version will be a bit less – though not

half, the power consumed depends mainly on vehicle duty and weight not

number of motors. Running time reduces with use on harder

driving surfaces.

All

in all - an interesting little run-about.

Here are some

short movie clips showing the single motor prototype in action........

Clip 1 (0.9 Mb)

Clip 2

(0.4 Mb) Clip

3 (1.5 Mb)

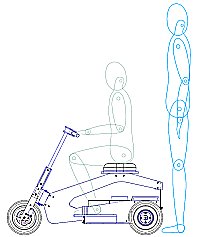

Have a look at

the general arrangement of the scooter to get an idea about size and

layout. The drawing is password protected and the password is:

sample

(click on the image)

Have a look at

the general arrangement of the scooter to get an idea about size and

layout. The drawing is password protected and the password is:

sample

(click on the image)

|