I

make regular use of small ball & socket joints in the

steering and suspension mechanisms of several of the

vehicles on the site. They are particularly useful for

joining steering actuation and track rods to front wheel

hub support assemblies where free rotation between the

joined components is needed about all three rotational

axes. I've also used them on panhard links in suspension

setups.

I

make regular use of small ball & socket joints in the

steering and suspension mechanisms of several of the

vehicles on the site. They are particularly useful for

joining steering actuation and track rods to front wheel

hub support assemblies where free rotation between the

joined components is needed about all three rotational

axes. I've also used them on panhard links in suspension

setups.

Small ball and socket joints are readily available and

fairly inexpensive. Both carbon steel and stainless

steel versions can be obtained with the stainless steel

joints being the more costly. Connecting thread sizes

between M5 and M16 are common with either right or left

handed threads available on the socket element of the

joint. Using opposite handed pairs on either end

of a connecting rod will allow fine length adjustment in situ

by rotating the connecting rod, however if very fine

adjustment is not needed and one joint can be

disconnected from the attached components for adjustment, same-handed joints can be

used on each end of the connecting rod - this

allows simple, inexpensive threaded bar to be used for the connected

rod.

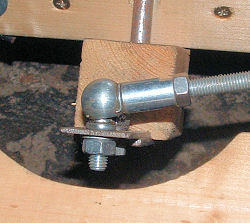

I

use the right-angled ball and socket joints mainly.

These generally have a higher push/pull load carrying

capacity than the in-line forms. For example

right-angled joints with M8 thread size and Ø13 mm ball

diameter have a max pull/push capacity of about 150kgf

which is adequate for most steering mechanism

applications I've designed.

I

use the right-angled ball and socket joints mainly.

These generally have a higher push/pull load carrying

capacity than the in-line forms. For example

right-angled joints with M8 thread size and Ø13 mm ball

diameter have a max pull/push capacity of about 150kgf

which is adequate for most steering mechanism

applications I've designed.

Attachment methods are fairly obvious - male threaded

stud on the ball element and a female threaded socket on

the socket element. Lock nuts should be used to lock the

socket element to the tie rod. One thing to note with

the right-angled forms is the limit of angular movement

which is roughly

±15° on the commonly available

units. This can represent a constraint in their

application and should be watched - forcing the joints

beyond their travel limits will induce bending moments

in the attached components and may cause the socket to

"pop" off the ball, so check for unrestricted travel on

assembly.