I've tried hard with all the designs to reduce as much as possible

the range of tools needed to build the karts and vehicles. This is

reflected in the designs - in the types of mechanical assemblies

I've made and the components and materials used. The best way to

understand the tooling required to build the vehicles is to study the plans and understand

the component shapes you would need to make - you can do this for

some of the designs with

the free plans.

Here's a general overview of the types of hand and power tools

that are likely to prove useful when building your own kart or

buggy.

The

types of timber used are predominantly planed softwood sections and

general purpose plywoods. On occasion hardwood blocks may be suggested

for bearing housings. For the woodwork then the usual range of DIY saws,

rasps etc will be needed. A

powered jig saw will help greatly with the profile cutouts in plywood

that make up the vehicle shaped panels. A bench mounted circular saw

will help in the important job of cutting straight edged lengths of

plywood for the gearbox casings and other vehicle structures.

The

types of timber used are predominantly planed softwood sections and

general purpose plywoods. On occasion hardwood blocks may be suggested

for bearing housings. For the woodwork then the usual range of DIY saws,

rasps etc will be needed. A

powered jig saw will help greatly with the profile cutouts in plywood

that make up the vehicle shaped panels. A bench mounted circular saw

will help in the important job of cutting straight edged lengths of

plywood for the gearbox casings and other vehicle structures.

A manual

mitre saw is a great though inexpensive way of cutting clean square ends

on timber lengths - important for screwed and/or glued abutting faces.

A manual

mitre saw is a great though inexpensive way of cutting clean square ends

on timber lengths - important for screwed and/or glued abutting faces.

A good powered drill is certainly needed for the metal parts (see below)

but is also needed for drilling accurately the timber parts, a selection

of flat tipped wood drills is needed to drill accurate holes such as

those used for bearing housings.

T

T he

metal parts of the vehicles have also been designed to reduce as far as

possible the metal working required - this varies between designs, some

need more metalworking than others.. However you will still need a good

hacksaw (with sharp blades), flat and circular section files are always

useful and a good powered drill should be to hand - preferably a proper

bench drill (drill-press), but failing that a powered hand drill mounted

in a bench drill stand.

he

metal parts of the vehicles have also been designed to reduce as far as

possible the metal working required - this varies between designs, some

need more metalworking than others.. However you will still need a good

hacksaw (with sharp blades), flat and circular section files are always

useful and a good powered drill should be to hand - preferably a proper

bench drill (drill-press), but failing that a powered hand drill mounted

in a bench drill stand.

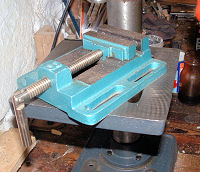

G

G et

a small vice to hold the metal workpiece when drilling - drilling

accurately positioned and sized holes in steel is simply not a job for a

hand held drill! You will need a selection of centre and properly

sharpened (best new) HSS twist drill bits for the hole sizes in the

parts shown in the drawings. Consider learning how to sharpen your twist

drill bits - sharp bits make life a lot easier.

et

a small vice to hold the metal workpiece when drilling - drilling

accurately positioned and sized holes in steel is simply not a job for a

hand held drill! You will need a selection of centre and properly

sharpened (best new) HSS twist drill bits for the hole sizes in the

parts shown in the drawings. Consider learning how to sharpen your twist

drill bits - sharp bits make life a lot easier.

Several

of the gearbox and steering shafts need flats ground on them for torque

transfer; you

could, with effort, do this with a hand file but far better to use a

grinding wheel attachment for your stand mounted drill or, even better

still, a proper bench mounted grinder - these days they are not

expensive.

Several

of the gearbox and steering shafts need flats ground on them for torque

transfer; you

could, with effort, do this with a hand file but far better to use a

grinding wheel attachment for your stand mounted drill or, even better

still, a proper bench mounted grinder - these days they are not

expensive.

I have for some time used a small model engineering size lathe for metal

turning work on the more advanced projects. I try to reduce the

need for this as much as possible however a lathe does allow you to do

some jobs at home that you might not otherwise be able to. Boring larger

diameter holes in gears or chain sprockets or in support plates, turning

down round bar prior to threading are some in addition to the usual

shaft turning. They are also the best tool for drilling straight and

accurately centred holes in gears and sprockets.

Aside

from the working tools you should give some thought to measuring,

marking off and checking your work.

A good centre punch, scribe and

accurate measuring tools will help, buy yourself some decent vernier

callipers; you can then check accurately the shaft and hole sizes. A

draftsman scale rule helps as does a good tape measure.

A good centre punch, scribe and

accurate measuring tools will help, buy yourself some decent vernier

callipers; you can then check accurately the shaft and hole sizes. A

draftsman scale rule helps as does a good tape measure.

F inally, other than the usual screw drivers, spanners etc you will need

to be able to drill and tap smallish diameter screw threads - so a

set of taps and dies will be helpful but particularly M6 and M8 (1/4" -

3/8") sizes. I've almost forgotten to mention that a good quality bench

vice mounted on a sturdy work bench will help greatly, "workmate" type

benches are also useful.

inally, other than the usual screw drivers, spanners etc you will need

to be able to drill and tap smallish diameter screw threads - so a

set of taps and dies will be helpful but particularly M6 and M8 (1/4" -

3/8") sizes. I've almost forgotten to mention that a good quality bench

vice mounted on a sturdy work bench will help greatly, "workmate" type

benches are also useful.

Finally

for the electrical work there are a few items that will help. Crimping

tools to suit the cable connectors you chose, a soldering iron will be

invaluable and invest in a decent multimeter - you may need it to

check out the wiring if (when) it doesn't work first time and to build

up your understanding of how the electrical circuits work!

Finally

for the electrical work there are a few items that will help. Crimping

tools to suit the cable connectors you chose, a soldering iron will be

invaluable and invest in a decent multimeter - you may need it to

check out the wiring if (when) it doesn't work first time and to build

up your understanding of how the electrical circuits work!

It should go without saying that the necessary safety precautions should

be taken when working with power tools - look after your eyes & fingers

especially, they are much more important than any kart you make.