Page 1

Page 2

Page 3

The different ways in which electric drive motors can be

connected to vehicle drive wheels is an area of interest for many DIY

kart and buggy builders.

Over the years I've tried a number of

approaches and here are a few suggestions -

Starting with

the simplest.

1. Fit the

Wheel directly on the Motor Shaft

..... don't! This won't work unless you are using a "hub

motor" - ie a type of low speed, high torque electric motor that is

specifically designed to carry a drive wheel. Generally these are quite

expensive, and the more commonly available drive motors run too fast and

with too low a torque for a direct drive to the wheels. You will

probably need at least a single stage speed reduction.....

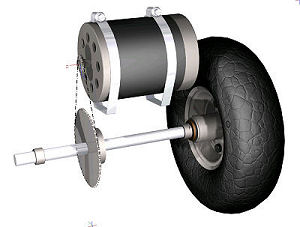

2. Single Stage Speed Reduction Stage

Most of the drive motors I use come fitted with a small

roller chain sprocket on the output shaft ready for assembly with a

chain transmission. Single stage reductions can also be implemented with

toothed belt transmissions or geared transmissions.

The

image shows a single stage roller chain drive to a rotating drive axle.

The wheel is fixed to the axle and the axle is bearing mounted (either

directly housed or by pillow block) on the vehicle chassis. This type of

arrangement works with vehicles with relatively fast turning wheels as

the size of the speed reduction that can be achieved is effectively limited by the

size of larger chain sprocket.

Extending the axle to carry the second rear drive wheel

provides a simple dual wheel drive, however one with no effective

differential action for cornering. To introduce good differential

behaviour use either an electric motor for each wheel (below left) or

fit a differential gear box (below right - single stage reduction drive

on a commercial kart).

The

single stage arrangement can be used for slower speed wheel drives if

used in conjunction with a drive motor with a built-in gear box (see

image left). These transmissions are effectively double or triple stage

reductions with the "gearhead" on the motor providing the first

reduction stages. The outcome is a lower speed / higher torque drive to

the wheels better suited to lower speed vehicles with smaller wheels or

for higher speed vehicles with larger wheels - in both low wheel rpm and

high drive torque is needed.

The

single stage arrangement can be used for slower speed wheel drives if

used in conjunction with a drive motor with a built-in gear box (see

image left). These transmissions are effectively double or triple stage

reductions with the "gearhead" on the motor providing the first

reduction stages. The outcome is a lower speed / higher torque drive to

the wheels better suited to lower speed vehicles with smaller wheels or

for higher speed vehicles with larger wheels - in both low wheel rpm and

high drive torque is needed.

The type of gearing in the

motor will affect it's behaviour - be careful with worm geared units if

you need regenerative braking.

....... go to Page 2 - Double Stage Reduction Drives