The

main vehicle chassis is a simple to build glued and screwed timber

construction. Ground clearance is fairly limited at roughly 50 mm (2") -

so the design is intended primarily for running on good drive surfaces

and not for off-road use. Should be okay on smooth (mown) grass

surfaces.

The

main vehicle chassis is a simple to build glued and screwed timber

construction. Ground clearance is fairly limited at roughly 50 mm (2") -

so the design is intended primarily for running on good drive surfaces

and not for off-road use. Should be okay on smooth (mown) grass

surfaces.

In use the kart will need

to be fitted with a strong karting style bucket seat to ensure the

driver is supported properly and the seat would be securely fixed to the

main chassis longerons. Seat belt attachments will also need to be fixed

securely to the main structural elements of the chassis towards the rear

of the seat.

A 36V reversing controller

will suit the design. The combined rated current draw of the two 750W

motors will be around 50 Amps, this will peak at over 100 Amps during

hard acceleration so a 100+ Amp 36V controller is probably required.

Assuming an average current draw of roughly half the rated current of

the motors the 3 x 12V 40 AmpH batteries should give roughly 1.5 hours

continuous use between charges (load and driving style

dependent).

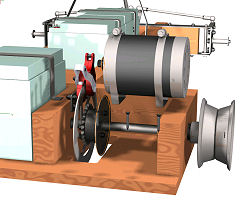

Some more images of the design -

Left

- the motor drive arrangement (some structure removed for clarity). I

thought it would be interesting to experiment with taper-lock

compression fittings here. The rear axle drive sprocket and brake disc

are mounted on a compression fitting "hub" made up from a heavy chain

sprocket and taper-lock bushing. The Taper Lock bush has a torque

capacity roughly 4-5 times the rated drive torque through the axle so it

should hold well and also be easy to fit on keyless shafting.

Left

- the motor drive arrangement (some structure removed for clarity). I

thought it would be interesting to experiment with taper-lock

compression fittings here. The rear axle drive sprocket and brake disc

are mounted on a compression fitting "hub" made up from a heavy chain

sprocket and taper-lock bushing. The Taper Lock bush has a torque

capacity roughly 4-5 times the rated drive torque through the axle so it

should hold well and also be easy to fit on keyless shafting.

The axles are supported in

needle roller bearings housed in the timber chassis structure.

Right- a view on the core elements of the kart (seat and

covers removed). As you can see the basic design is fairly simple and

has scope for individual customisation - eg steering wheel choice,

seating and choice of colours. Covers will be required to keep curious

fingers out of the chain drive area.

As always with electric drives care should be taken when

working at and around the hot motors.

Batteries should be securely strapped down to the

chassis.

As I mentioned I haven't

yet found the time to build and test the design. It looks to me as if it

should work though - I'll keep you posted.