|

Two Stage Roller Chain Drive

To

get the most compact transmission designs try using all-geared

reduction stages. These are trickier to build because of the

control that needs to be maintained over shaft separation and

parallelism but can provide fairly large speed reductions. To

get the most compact transmission designs try using all-geared

reduction stages. These are trickier to build because of the

control that needs to be maintained over shaft separation and

parallelism but can provide fairly large speed reductions.

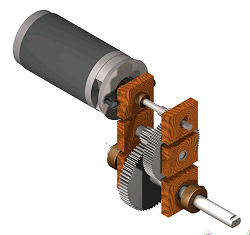

The image shows a two stage

straight spur gear drive transmission with a 250W electric

wheelchair motor. With, for example, two 8:1 spur gear

reduction stages the arrangement would give a total speed ratio

of 64:1 in a fairly compact space - good for some low speed high

drive torque applications.

The straight spur gearing can

also be driven from the output shaft so will not lock-up if the

power is removed from drive motor, this allows the road wheel to

drive the motor as a generator for regenerative braking

applications. |