Page 1 Page 2

Page 3

3. Double Reduction Stage Drives

Typical electric drive motors will have maximum shaft

speeds around the 2500 - 3000 rpm mark. A single stage reduction will

give maximum reductions of roughly 5 or 6:1, given practical constraints

on the sizes of available sprockets and space to fit them in. This

leaves drive wheel speeds of roughly 400 - 500 rpm when the motor

runs at top speed. For many small wheeled slow speed EV's this is too

fast, and the lack of reduction ratio can also mean lack of drive torque

at the wheels (and conversely torque overload at the motor shaft).

At the bottom of Page 1 a solution is described using

electric drive motors with built-in gearheads, however these are not

always available and the solution might be to build your own two stage

speed reduction.

Some examples:

|

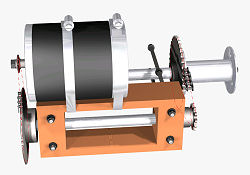

Two Stage Roller Chain Drive

With

this set up a bearing mounted intermediate shaft is driven by

the roller chain stage from the electric motor output shaft. The

intermediate shaft carries a second sprocket which drives a

second roller chain stage to the vehicle's road wheel - here the

final drive sprocket is mounted directly on the wheel hub which

is bearing supported on a fixed shaft. With

this set up a bearing mounted intermediate shaft is driven by

the roller chain stage from the electric motor output shaft. The

intermediate shaft carries a second sprocket which drives a

second roller chain stage to the vehicle's road wheel - here the

final drive sprocket is mounted directly on the wheel hub which

is bearing supported on a fixed shaft.

With, say, 5:1

reductions at each stage this arrangement will give a 25:1

overall speed reduction. This will reduce a motor shaft speed of

2500 rpm to 100 rpm at the road wheel with a proportionate

multiplication of drive torque through the transmission - there

is a lot of scope for adjusting the overall speed ratios by

changing either or both of the stage sprocket sizes. |

|

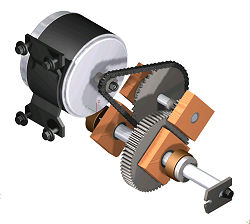

Roller Chain

+ Geared Drive

Here a combination of roller

chain and straight spur gear stages are used to produce a two

stage transmission. The roller chain element allows flexibility

in the mounting of the electric motor and the spur gear stage

provides a compact high reduction stage.

Both shafts rotate and are

bearing mounted and the vehicle's road wheel is torque fixed to

the final drive shaft. Note how the final shaft diameter is the

larger - it has to deal with both larger drive torques and

bending loads from the road wheel.

The intermediate and final shaft

separation has to be carefully controlled to maintain the

correct centre distance for the gear mesh. |

|

Double stage chain drive as used

in the Voiturette

|

Combined chain & gear drive as

used in the 500W Kart |

....... go to Page 3 - More Double Stage Reduction

Drives